MECANIC SUD INDUSTRIE – MSI

Special processes and hard metal machining and assemblies

PRESENTATION

Created in 1977 and 1st company of the Rochette Industrie Group, Mecanic Sud Industrie grew around special processes integration along with its machining capabilities.

Key player in the Oil & Gas subcontracting panel in France and WorldWide, MSI is now qualified as per EN9100 for Aeronautics

Following CAP2020 Group policy, its HVOF for chromium carbide is REACH compliant and will lead its development in the Aeronautics market.

Our Customer

If you want to watch our video, please fill in our contact for to get the connection link

MANUFACTURING

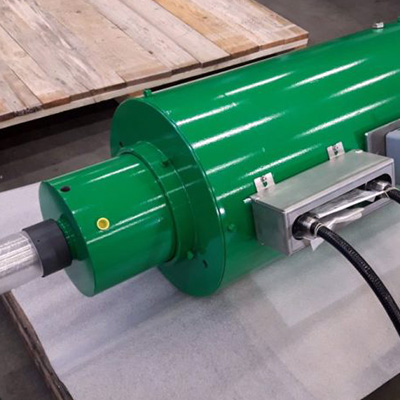

Year after year, MSI integrated the capacity to manufacture turnkey components, our special processes are completed by cylinder grinding and non destructive examination. Organized around our Navision ERP, the manufacturing can be handled by spot orders or Forecast/Opened Orders

HVOF and other special processes

MSI integrated on its manufacturing site the laser metallization technology and surface treatment and cladding special processes with high added value:

PTA (Plasma Transferred Arc): welding metallization,

HVOF (High Velocity Oxy Fuel): supersonic projection, NADCAP Certified

QPQ (Quench Polish Quench): nitrocarburation in salt bath,

LASER (Rechargement Laser) : semi additive manufacturing process.

Type of added metal :

Inconel, tungsten carbide, satellite, bronze, chromium carbide, etc…

Painting :

First coating, second coating Xylan, Everslick, Phosphating. Can be certified by NORSOK inspectors.

Machining and assembly

Metal and alloys machined :

Steel, stainless steel, inconel, titanium, duplex steel, copper and aluminum alloys

Internal and external turning of parts up to 800mm diameter (32’’) and a maximum length of 3050mm (120’’)

Milling up to 4000x1500x1200mm (160”x 60’’x 50’’) and maximum weight of 5 tons

Manufacturing of single parts of medium sized batches

Manufacturing and test of mechanical and hydraulic assemblies (up to 15000 PSI – 700 bars)

Subcontractor for Parts and assemblies

Machining – special proceses – integration:

Thanks to its experience in integrating high value equipments and assemblies manufacturing, MSI is able to industrialize a complete product as per a customer’s specifications.

Project management of complete manufacturing :

Project management in MSI is targeted to tackle the challenges by direct coordination with its customer’s design department (type design to cost). MSI also adapt its organization for series life to optimize costs and lead time.

Coordinate a network of know-how to guarantee project fulfillment :

MSI’s subcontractors have the expertise and versatility that complete its capabilities and insure the delivery of a complete product. Simultaneously, MSI adapt proactively its production priorities in order to match its customer’s needs.

Quality Control

Non destructive examination (NDE) is a set of technologies used to confirm the integrity of structures of materials with no impact on their condition. It can be mobilized during manufacturing, during use of the product or in aftermarket.

Visual examination

Dye Penetrant

Magnetic testing

Ultrasonic testing